Microwave sintering equipment can be used to sinter various high quality ceramics, lithium cobalt oxide, silicon nitride, silicon carbide, aluminum oxide, aluminum nitride, zirconia, magnesium hydroxide, aluminum, zinc, kaolin, cobalt sulfate, cobalt oxalate, five Vanadium oxide, phosphogypsum/gypsum, etc.; sintered electronic ceramic devices: PZT piezoelectric ceramics, varistors, etc.

The Si_3N_4 ceramic was sintered by microwave sintering technique and conventional pressureless sintering technique. The composition and microstructure of Si_3N_4 samples sintered by different techniques were studied by XRD and TEM. The flexural strength and fracture toughness of the two samples were measured by three-point bending and indentation. The results show that the introduction of N 2 gas pressure can effectively control the decomposition of Si_3N_4 during microwave sintering. Microwave sintering can greatly reduce the densification temperature of Si_3N_4, increase the phase transformation speed, shorten the sintering time, and improve the mechanical properties.

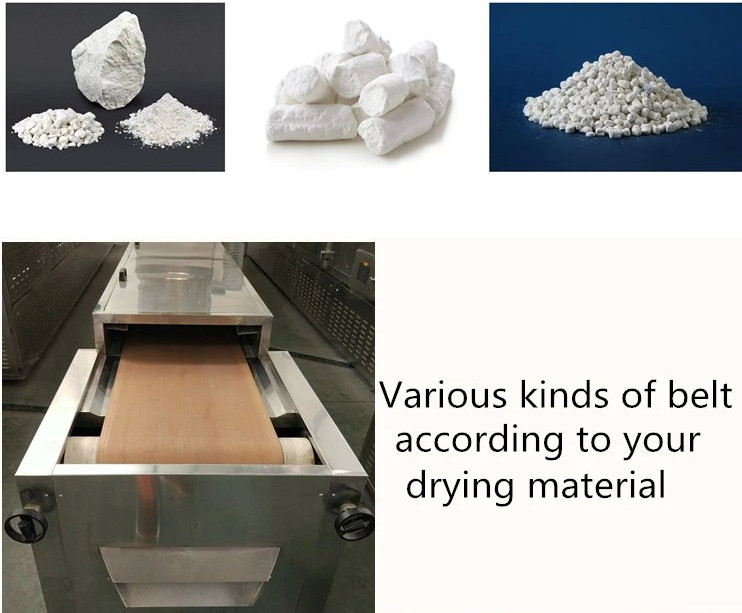

Product Details

| Condition | New | Application | Kaolin Sintering Machine | |

| Type | Kaolin Sintering Machine | Product name | Microwave Machine | |

| Place of Origin | Shandong, China (Mainland) | Heating source | Electricity | |

| Brand Name | Leader | Material | 304 Stainless Steel | |

| Model Number | TB - Microwave Machine | Color | Silver Gray | |

| Voltage | 220v/380v | Capacity | 120 - 1800 kg / h | |

| Power(W) | 12kw ( customize ) | Control system | PLC | |

| Dimension(L*W*H) | 7010*840*1750 ( customize ) | Transmission speed | 0 - 10 m / min (adjustable) | |

| Weight | 3t | Function | Drying , Sterilization , Roasting | |

| Certification | CE Certificate | After-sales Service Provided | Engineers available to service machinery overseas | |

| Name | High Quality Tunnel Microwave Kaolin Sintering Machine | Warranty | 1 Year |

| Item | LD-200KW | LD-30KW |

| Power supply | 380V,50Hz | 380V,50Hz |

| 3phase 5 line | 3phase 5 line | |

| Related input apparent power | ≤ 230KVA | ≤ 38KVA |

| Microwave output power | ≥200KW | ≥ 30KW |

| Temperature range & accuracy | 0-200℃;1℃ | 0-200℃;1℃ |

| Relative humidity | ≤80% | ≤80% |

| Inlet and outlet height | 80mm(adjustable) | 80mm(adjustable) |

| Microwave power adjust range | 0-200KW | 0-30KW |

| Transport belt width | 1200(adjustable) | 750mm(adjustable) |

| Outline size(mm)(LXWXH) | 16200x1800x1750(adjustable) | 8500x1500x1750(adjustable |

| Transmission speed | 0-8m/min(adjustable) | 0-8m/min(adjustable) |

| Microwave output frequency | 2450 ± 50MHZ | 2450 ± 50MHZ |

| Environment temperature | 0-50℃ | 0-50℃ |

| LD-40KW | LD-60KW | LD-100KW |

| 380V,50Hz | 380V,50Hz | 380V,50Hz |

| 3phase 5 line | 3phase 5 line | 3phase 5 line |

| ≤ 50KVA | ≤ 72KVA | ≤ 130KVA |

| ≥40KW | ≥60KW | ≥100KW |

| 0-200℃;1℃ | 0-200℃;1℃ | 0-200℃;1℃ |

| ≤80% | ≤80% | ≤80% |

| 80mm(adjustable) | 80mm(adjustable) | 80mm(adjustable) |

| 0-40KW | 0-60KW | 0-100KW |

| 750mm(adjustable) | 1200(adjustable) | 1200(adjustable) |

| 10500x1500x1750(adjustable) | 10500x1800x1750(adjustable) | 16200x1800x1750(adjustable) |

| 0-8m/min(adjustable) | 0-8m/min(adjustable) | 0-8m/min(adjustable) |

| 2450 ± 50MHZ | 2450 ± 50MHZ | 2450 ± 50MHZ |

| 0-50℃ | 0-50℃ | 0-50℃ |

★Using stepless adjustable, high stability, long life, continuous wave industrial grade microwave source to ensure continuous and long-term operation of the equipment.

★ Use a high-precision infrared thermometer to directly measure the sample temperature.

★Equipped with embedded microcomputer control system, it provides three operation modes: manual, automatic and constant temperature, and can be switched freely.

★ A variety of original special 坩埚 can be selected, no pollution to materials.

★ It can process and process materials with different degrees of microwave coupling, and has good versatility.

★ Set corrosion-resistant exhaust passage to quickly discharge the gas discharged during the heating process.

★ Real-time temperature graph display to achieve dynamic monitoring of the heating process.

★ Safe and reliable microwave shielding cavity design, multiple anti-leakage protection.

Supply Ability: 100 Set/Sets per Month Urgent order inform us in advance

Packaging Details Inside: plastic bag.

Outside: wooden case (adopt the wooden case or wooden pellets depended on clients' requirement).

Functions&Features:

♦Drying: The microwave dryer is used to dry green tea leaf in a short time.

♦Sterilization: The fungus, mycetes and others can be killed by the microwave dryer during the drying process.

♦Fast and evenly: The microwave dryer can change to be heat within several seconds,so the equipment is very efficent.

♦keeping fresh: The sterilization is with lower temp, so the color,taste and nutrition of the tea can be protected well.

♦Safe: The microwave is passing in the metal covered rooms and waveguide without leaking. It will not generate extra heat and pollution.

♦Simple to operate: The PLC system is simple, stable, safe and friendly,so it is convenient to use.

The propagation of the sintering wave during microwave sintering is much more uniform than the conventional heating method. The metal is sintered to a ceramic by microwave irradiation to a high temperature of 1300-2000 ° C. Experiments have shown that when the compactness of the sample is high, the propagation rate of the combustion wave caused by the conventional heating method is greatly reduced, and it is not natural because of "self-extinguishing". However, if microwave irradiation is used, since the temperature rise is the result of the absorption (or diffusion) of the microwave energy by the reaction substance itself, as long as the microwave source continuously supplies energy, the sample temperature will quickly reach the ignition temperature (T1). Once the reaction is initiated, the heat released causes the sample temperature to rise further to the combustion temperature (T2), and the ability of the sample to absorb microwave radiation also increases, which ensures that the reaction can be maintained at a sufficiently high temperature (T3>T1). Carry on until the reaction is complete. Microwave combustion synthesis or microwave sintering is a process that can be controlled. That is to say, we can artificially control the propagation of combustion waves by adjusting a series of parameters according to the requirements of the nature of the product. This is a significant advantage of microwave combustion synthesis over conventional techniques. Microwave power can be adjusted directly by using a microwave source with adjustable power to control the absorption (or dissipation) of microwave energy by the sample.

Equipment Parameters:

| NO. | Model | Power(kw) | Dehydration capacity(kg/h) | Sterilization capacity(kg/h) | Size(mm) |

| 1 | TB-12KWSP | 12 | 12 | 120-150 | 7010*840*1750 |

| 2 | TB-20KWSP | 20 | 20 | 190-240 | 9350*840*1750 |

| 3 | TB-30KWSP | 30 | 30 | 300-380 | 11690*840*1750 |

| 4 | TB-40KWSP | 40 | 40 | 390-500 | 10520*1060*1750 |

| 5 | TB-50KWSP | 50 | 50 | 500-630 | 11690*1060*1750 |

| 6 | TB-60KWSP | 60 | 60 | 600-750 | 12860*1060*1750 |

| 7 | TB-70KWSP | 70 | 70 | 700-870 | 14030*1060*1750 |

| 8 | TB-80KWSP | 80 | 80 | 800-1000 | 12680*1200*1750 |

| 9 | TB-100KWSP | 100 | 100 | 1000-1250 | 15200*1200*1750 |

| 10 | TB-150KWSP | 150 | 150 | 1500-1850 | 21050*1200*1750 |

| 11 | TB-200KWSP | 200 | 200 | 2000-2500 | 25050*1200*1750 |

Packaging & Shipping

1. Daub coal oil on the surface of the machines.

2. Plastic film as the inner packing.

3. Standard export wooden case as the outer packing.

4. Train, ship or depend on clients' requirement

We will provide best and thoughtful service for you :

1). Free consultation service before, during, and after sales.

2). Free project planning and design services upon clients' special demands.

3). Debugging and inspecting of equipment until everything is functional before leaving the factory.

4). Overseas installation and training of equipment maintenance and operating personally.