Bottled beverage microwave sterilization equipment is used for the sterilization of bottled liquid materials (fruit wine, cocktails, condiments, juices).

Processing technology of Bottled beverage microwave sterilization equipment: bottled materials - feeding system - feed energy suppressor - microwave sterilizer - discharge energy suppressor - cooling system

Bottled beverage microwave sterilization equipment features:

1, the sterilization time is short;

2, the sterilization temperature is low and uniform, to maintain the original flavor of the product;

3, sterilization speed, large output.

4, energy efficient. The microwave acts directly on the material, so there is no additional heat loss, the air in the furnace and the corresponding container will not heat, so the thermal efficiency is extremely high, the production environment is also obviously improved, and the electricity can be saved by 30% compared with the far infrared heating. .

5, easy to control, advanced technology. Compared with the conventional method, the device is ready to use; without thermal inertia, the operation is flexible and convenient; the microwave power is adjustable. In microwave heating, drying, no waste water, no waste gas, is a safe and harmless high-tech. Improve product quality and bring economic benefits

Basic parameters of microwave food bottle sterilization machine:

Model: Bottled beverage microwave sterilization equipment

Input power: three-phase 380±10% 50HZ;

Frequency: 2450±50MHz

Microwave output power: 10-300KW (adjustable)

Rated input apparent power: 10-300 KW

Ambient temperature: 5~40°C

Relative humidity: ≤80%

Transmission speed: 0.5~30m/min (adjustable) with automatic deflection structure

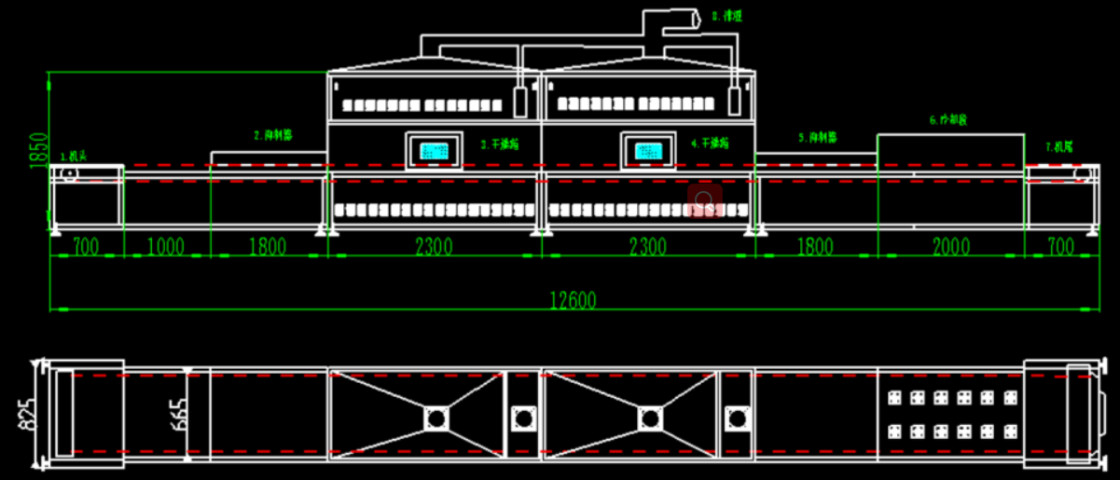

Dimensions: customized according to customer needs

Microwave leakage: in line with national GB10436-89 standard (≤1mw/cm2)

Microwave food bottle sterilizer features: low temperature sterilization to maintain nutrients and traditional flavor, microwave energy can penetrate the inside of the food, the frequency is tens of thousands of oscillations per second, killing bacteria through special thermal and non-thermal effects, compared with conventional thermal sterilization The desired disinfection effect can be obtained at a relatively low temperature and in a short period of time.

The characteristics of the bottled beverage microwave sterilization equipment are as follows:

1. Selective heating. Since water molecules are best for microwave absorption, the portion with a high water content absorbs more microwave power than the portion with lower water content. This is the characteristic of selective heating, which can achieve the purpose of uniform heating and uniform sterilization.

2. Energy saving and efficient. The microwave acts directly on the material, so there is no additional heat loss, the air in the furnace and the corresponding container will not heat, so the thermal efficiency is extremely high, the production environment is also obviously improved, and the electricity can be saved compared with the far infrared heating.

3. Short time and high efficiency. Microwave heat sterilization is a process in which the object to be heated itself becomes a heating element and does not require heat conduction. The microwave penetrates the inside and outside of the object from all sides and at the same time enables the object to achieve uniform heat sterilization in a short time, which greatly shortens the drying sterilization time, thereby improving the yield.

4. Easy to control and advanced technology. Compared with the conventional method, the device is ready to use; without thermal inertia, the operation is flexible and convenient; the microwave power is adjustable, and the transmission speed is adjustable. In the microwave heating drying sterilization, no waste water, waste gas, waste residue, is a safe and harmless high-tech.

The sterilization effect is good. Practice has proved that the use of microwave sterilization generally kills E. coli at 70-80 ° C, the total number of bacteria is greatly reduced, the time is only 1-2 minutes. The speed is fast and the time is short, so the nutrients in the food and the traditional flavor are retained to extend the shelf life. Microwave sterilized materials can extend the shelf life of half a year, and have a significant effect on improving product quality and extending storage cycle. UV sterilizing system can be added. In addition, an ultraviolet sterilization system can be added to further ensure the sterilization effect, and at the same time prevent the swelling of the plastic bag during the drying sterilization process.